What is HVLP?

The HVLP turbine spray gun was developed to meet market requirements

At the beginning of the ‘80ies, in the United States, the South Coast Air Quality Management District (SCAQMD) in Los Angeles and other bodies charged to check air quality, were troubled by the damage organic volatile chemical substances (VOC) caused to air quality. They issued strict regulations which set the minimum transfer efficency of painting guns to 85% at a pressure below 10psi (0.70bar). The more the product could reach the surface to be painted, the less it was wasted and dispersed in the air.

Because of the new standards, the leading manufacturers of high pressure guns had to find a solution to increase the efficiency of their products where the transfer capacity was notoriously poor. As a consequence, they conceived guns that could convert the high pressure air supplied by compressors into low pressure air.

These guns called HVLP (high volume low pressure) could fulfil all legal provisions with the sole restriction of using a min. 10 hp compressor because air consumption was higher than 20 cubic feet per minute (cfm).

The HVLP turbine spray gun was developed to meet market requirements already in Rigo since 1965..

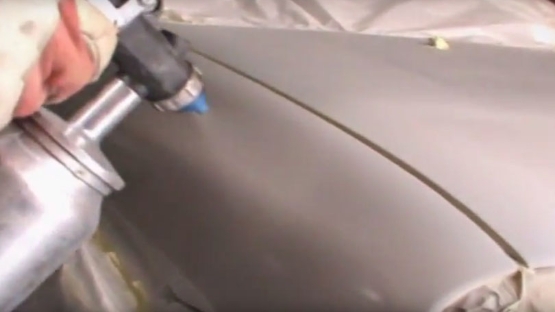

The system is using a small but powerful turbine that can deliver a high air flow through a tube in order to supply the spray gun that can provide for a transfer capacity above 85% and, in special cases, even above 95%.

Every single component – turbine, tube and spray gun – is playing an important role in the whole system.

The demand for this compact and light equipment is constantly increasing in consideration of the tendency to limit polluting emissions for environmental protection in many countries.

A tendency also confirmed by varnish producers orienting part of the research / development towards the creation of more “ecological” products, such as water-based or solid content products (with a low content of solvents) that can however give good application results.